Safety stock is a term used in logistics and inventory management that refers to the additional amount of inventory that is kept on hand to mitigate the risk of running out of stock (stockouts) due to uncertain demand or lead time. A safety stock formula helps determine amount of safety stock needed. Having a sufficient amount of safety stock can help to avoid lost sales and customer dissatisfaction due to the unavailability of products, as well as to smooth out production and delivery schedules.

On the other hand, carrying too much safety stock can increase carrying and holding costs, as well as the risk of obsolete products and waste. Therefore, finding the right balance between having enough safety stock to meet customer needs and avoiding excess inventory is an important aspect of supply chain management.

How Do You Find the Right Balance Between Enough and Too Much Safety Stock?

Several factors need to be considered when determining the appropriate level of safety stock for a given product or SKU (Stock Keeping Unit). These include the forecasted demand for the product, the lead time required to obtain more inventory, and the variability in demand and lead time.

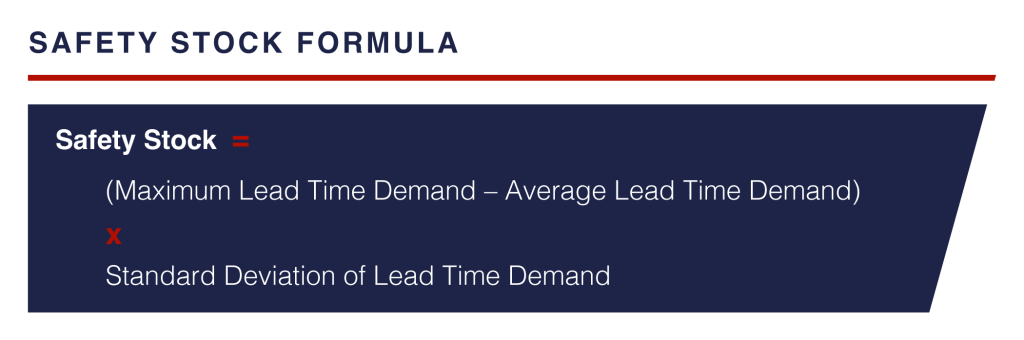

The basic safety stock formula is as follows:

The maximum lead time demand is the greatest number of units that are expected to be demanded during the lead time. The average lead time demand is the typical number of units that are expected to be demanded during the lead time. The standard deviation of lead time demand is a measure of the variation in demand during the lead time.

For example, let’s say that the maximum lead time demand for a product is 50 units, the average lead time demand is 40 units, and the standard deviation of lead time demand is 10 units. The safety stock for this product would be (50 – 40) x 10 = 100 units.

It’s important to note that this safety stock formula assumes a normal distribution of demand, which means that the demand follows a bell curve with a predictable mean and standard deviation. In reality, demand is often not normally distributed and can be influenced by various factors such as seasonality, promotions, and market trends. In these cases, the safety stock formula may need to be adjusted to account for these factors.

One way to do this is to use statistical forecasting techniques such as exponential smoothing or autoregressive integrated moving average (ARIMA) models to accurately predict demand and lead time. These techniques can help to identify patterns in demand and lead time and provide more accurate forecasts, which can in turn be used to determine the appropriate level of safety stock.

Another factor that can impact the safety stock calculation is the safety stock policy that a company chooses to adopt. Companies can use several different safety stock policies, each with its own pros and cons.

Order-Up-To Policy

The first policy is the “order-up-to” policy, in which the safety stock is set at a fixed level and the inventory is replenished when it reaches that level. This policy is simple to implement and can be effective in situations where demand is relatively stable and predictable. However, it can also result in excess inventory if demand turns out to be lower than expected.

Periodic Review Policy

The second policy is the “periodic review” policy, in which the safety stock is reviewed and adjusted regularly, such as monthly or quarterly. This policy allows for more flexibility in adjusting the safety stock to changes in demand and lead time, but it can also be more time-consuming and resource-intensive to implement.

Continuous Review Policy

The third policy is the “continuous review” policy, in which the safety stock is continuously monitored and adjusted in real time based on changes in demand and lead time. This policy can be more effective in highly dynamic environments where demand and lead time can change rapidly, but it requires a more advanced IT infrastructure and real-time data availability, as well as more frequent and shorter lead times for replenishment.

What Other Safety Stock Policies Are At Companies’ Disposal?

In addition to these safety stock policies, other strategies can be used to manage inventory and minimize stockouts, such as just-in-time (JIT) inventory systems, vendor-managed inventory (VMI), and consignment inventory. These strategies involve closer collaboration and information sharing with suppliers and customers and can help to reduce the need for safety stock by improving the accuracy of demand forecasts and reducing lead times.

Ultimately, the right safety stock strategy and safety stock formula will depend on the specific needs and constraints of a company and its supply chain. It’s important to regularly review and optimize the safety stock levels to ensure that they are sufficient to meet customer needs without resulting in excess inventory and unnecessary costs. By using a combination of forecasting techniques and inventory management strategies, companies can effectively balance the trade-off between the cost of stockouts and the cost of carrying safety stock.

A sound safety stock formula minimizes supply chain disruptions by ensuring that there is a sufficient amount of inventory available to meet customer demand, even in the face of uncertainty or variability in demand or lead time. This can help to avoid stockouts, which can lead to lost sales and customer dissatisfaction.

How Will A Solid Safety Stock Help Get Rid of Supply Chain Disruptions?

Having a safety stock formula can also help to smooth out production and delivery schedules, as it allows for some flexibility if demand is higher or lead times are longer than expected. This can help to avoid bottlenecks or delays in the supply chain, which can have cascading effects on other parts of the supply chain and result in disruptions.

Additionally, having a safety stock formula that is based on accurate demand and lead time forecasts, as well as an appropriate safety stock policy, can help to minimize excess inventory and the associated costs of carrying and holding excess inventory. This can help to optimize the use of resources and improve the overall efficiency of the supply chain.

Overall, a sound safety stock formula helps to mitigate the risks and uncertainties of the supply chain and enables companies to provide reliable and consistent service to their customers.